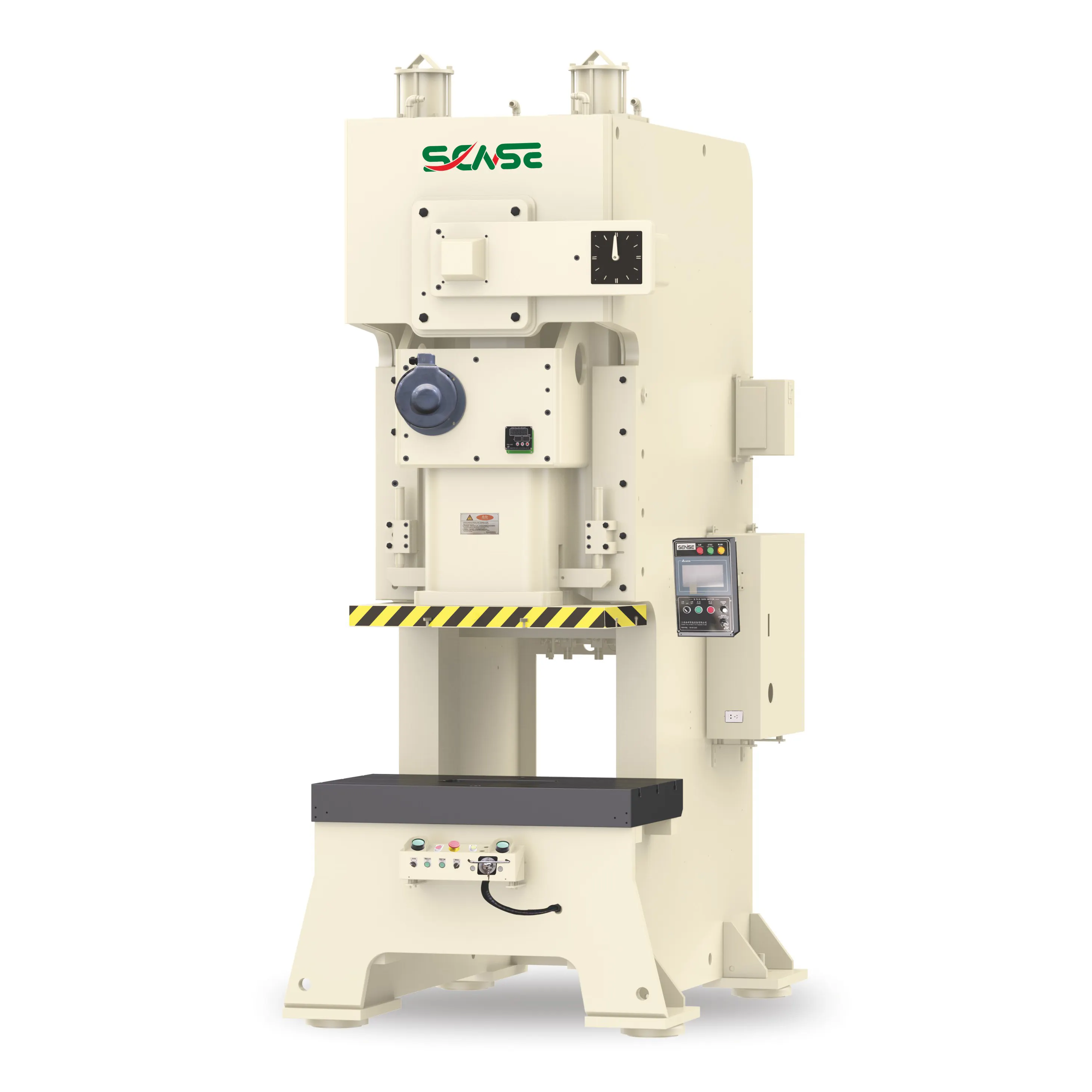

Optimal C-Type Press Review & Buying Guide

C-Type presses have seen significant technological advancements, enhancing their precision and efficiency. These improvements, including higher maximum force and faster cycle times, contribute to increased productivity and reduced operational costs. The integration of smart technologies, such as real-time monitoring and predictive maintenance, further bolsters equipment reliability and reduces downtime. These enhancements are particularly beneficial in industries like fine art and limited edition projects, where consistent quality is crucial. Beyond these creative fields, the advancements in C-Type presses offer substantial benefits to sectors including automotive manufacturing, electronics, and large-scale industrial applications. In commercial printing, the increased precision and efficiency can enhance throughput and reduce the environmental footprint through better material usage and more efficient workflows. Sustainable practices are further supported by real-time data analysis, which enables accurate demand forecasting and inventory optimization. The seamless integration of these technologies into supply chain management systems helps in achieving a more sustainable and efficient overall process.

Important Considerations for C-Type Press Buyers

When selecting a C-type press, buyers must carefully consider a range of factors to ensure that the investment will meet their needs both in the short and long term. Balancing initial cost with performance is crucial, as advanced features such as automation and digital controls, while offering significant long-term benefits through reduced maintenance, increased uptime, and improved efficiency, often require a higher upfront investment. Buyers should also evaluate the long-term environmental and sustainability impacts, such as energy efficiency and the use of recyclable materials, which can reduce operational costs and align with corporate responsibility goals. Additionally, the integration of smart technologies and data analytics can further enhance operational efficiency and sustainability. Industry standards and certifications, like ISO 9001 and CE, are essential for ensuring quality and compliance, thereby building client trust and opening up new market opportunities.

Real-World Experiences and Challenges with C-Type Presses

Real-world experiences with C-type presses demonstrate significant advancements in precision and material handling, particularly in industries such as aerospace and automotive. The implementation of servo-driven systems and advanced closed-loop control has improved accuracy, reducing errors and increasing productivity. These technological improvements allow for the efficient processing of advanced composites and thin-wall components, which is crucial for meeting stringent demands in highly regulated sectors like medical manufacturing. Similarly, the integration of smart technology and IoT enhances C-type presses by enabling real-time monitoring, predictive maintenance, and compliance with regulatory standards. Case studies show that companies have achieved notable reductions in downtime and increased overall equipment effectiveness through the use of IoT sensors and data analytics. However, challenges such as integrating legacy systems with new technologies and maintaining sterility in environments like clean rooms remain significant but can be overcome with strategic planning and implementation.

Comparative Analysis of C-Type Presses with Other Types

Here is a comparative analysis of C-type presses with hydraulic and servo presses, highlighting key differences and similarities:

- Precision and Flexibility: C-type presses stand out for their versatility and high positional accuracy, often outperforming hydraulic presses in multi-stroke operations. However, they may not match the precision and adaptability of servo presses, which excel in complex, high-speed tasks.

- Cost-Effectiveness: C-type presses offer better cost-effectiveness for smaller workloads and high-volume, repetitive tasks, making them a preferred choice for manufacturers aiming for low initial investment. In contrast, servo presses tend to be more expensive upfront but are worth considering for their long-term savings and reduced downtime.

- Speed and Energy Efficiency: Servo presses generally outpace C-type presses in terms of speed and energy efficiency, catering to large-scale, fast-turnaround applications. C-type presses, while reliable and cost-effective, may prove less efficient for high-speed production lines.

- Maintenance and Component Longevity: C-type presses are generally easier to service with lower ongoing costs but may need more frequent die and shuttle replacements, leading to higher long-term maintenance costs. Servo presses, though more challenging to maintain, often result in lower maintenance costs over time due to fewer component replacements and superior efficiency.

- Environmental Impact: C-type presses consume more energy and generate higher waste due to frequent die replacements. Strategies such as using longer-lasting and recyclable materials, implementing energy-efficient technologies, and integrating IoT and smart sensors can mitigate these environmental challenges.

Market Trends and C-Type Press Reviews

Market trends in C-type presses are increasingly focusing on sustainability and efficiency, driven by consumer demand for environmentally friendly products. Press manufacturers are integrating smart technologies such as IoT and AI for real-time monitoring and predictive maintenance, which not only enhance efficiency but also provide substantial cost savings. Renewable energy solutions, including solar panels and wind turbines, are being incorporated to further reduce the environmental footprint of these presses. Additionally, many manufacturers are adopting industry certifications and benchmarks like CE, Energy Star, and ISO standards to ensure their products meet high sustainability and efficiency standards. As these advancements continue to evolve, training programs and support structures are being developed to ensure operators and maintenance personnel can effectively manage the sophisticated systems. This comprehensive approach positions C-type presses as integral components in the modern, sustainable manufacturing landscape, supporting both large and small businesses in their production goals.

Key Features and Maintenance Guidelines for C-Type Presses

When selecting or reviewing C-Type presses, consider the following key features and maintenance guidelines:

- Modular Design: Enhances flexibility and ease of customization, making it ideal for diverse production needs. Modular components can be easily accessed for routine maintenance, reducing downtime.

- Hydraulic Systems: Provide smoother operation and better precision, which translates to enhanced efficiency and reduced wear and tear over time. Regular maintenance becomes more focused and requires less effort.

- Variable Speed Drives: These features significantly improve energy efficiency, allowing for precise control over the press speed and reducing electricity usage. This contributes to a more sustainable operation.

- Real-Time Data and Predictive Maintenance Tools: By integrating IoT sensors, predictive analytics can monitor press performance and alert maintenance teams to potential issues. This proactive approach helps in scheduled downtime and reduces unscheduled stops.

- Digital Twins and Simulation Software: These tools facilitate fine-tuning of press settings and reduce setup times. Virtual simulations can optimize operations and improve overall equipment effectiveness (OEE) and quality control.

FAQs Related to C-Type Presses

What are the key technological advancements in C-Type presses that enhance their efficiency?

C-Type presses have seen advances in higher maximum force, faster cycle times, and integration of smart technologies like real-time monitoring and predictive maintenance, which contribute to increased productivity and reduced operational costs.What are the important considerations for buyers when choosing a C-Type press?

Buyers should consider balancing initial costs with performance, evaluating long-term environmental and sustainability impacts, and integrating smart technologies and data analytics for operational efficiency and cost savings. Additionally, industry standards and certifications are crucial for ensuring quality and compliance.What are some of the challenges faced with the implementation of C-Type presses in real-world applications?

Challenges include integrating legacy systems with new technologies and maintaining sterility in environments like clean rooms. However, strategic planning and implementation can help overcome these issues.How do C-Type presses compare to hydraulic and servo presses in terms of precision and cost-effectiveness?

C-Type presses provide high positional accuracy and are more cost-effective for smaller workloads and high-volume, repetitive tasks. In contrast, servo presses offer better speed and energy efficiency for large-scale, high-speed production, but are more expensive upfront.What market trends are driving advancements in C-Type press technology?

Market trends are pushing for more sustainability and efficiency, with a focus on integrating smart technologies, renewable energy solutions, and achieving industry certifications like CE, Energy Star, and ISO standards to support environmentally friendly and cost-effective manufacturing practices.