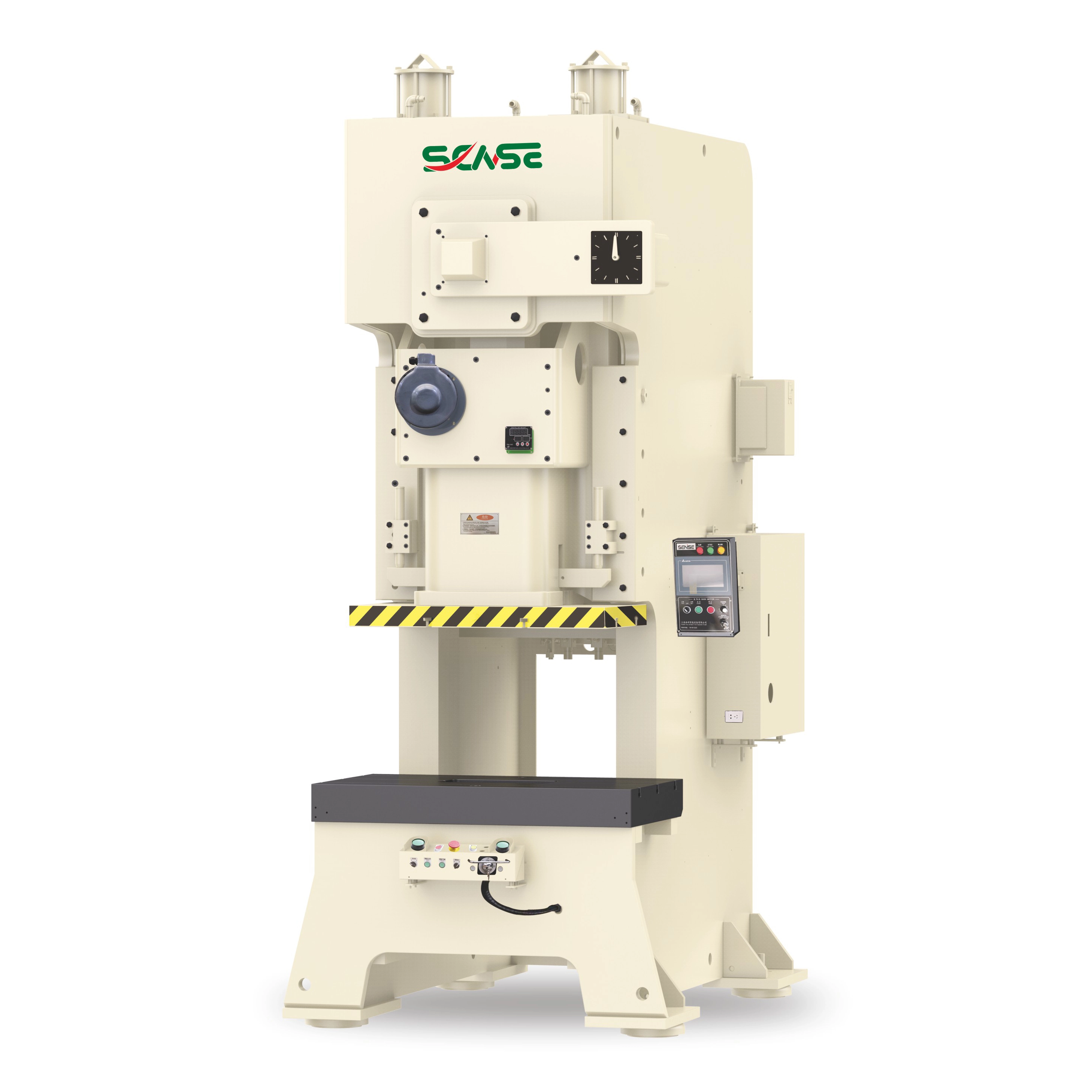

SKA Elbow Type Single Crankshaft Open Punch

● This series of punch presses are high-tech cold forging presses. In order to meet such high-precision requirements, Sense developed a high-rigidity body structure to ensure that the precision of the slider can fully meet the production requirements of any customer's factory.

● This series can be applied to produce diversified products, and provide high efficiency and high precision manufacturing processes.

● The load mechanism adopts a high rigid structure, which can greatly reduce the deformation of the body, which can not only maintain the accuracy of the product but also increase the service life of the mold.

● The heavy-duty toggle motion curve of this series approaches the surface of the workpiece at a slow speed, resulting in smooth plastic processing, ensuring the stability of the production process and the precision of the product.

● When any abnormal overload situation occurs, the overload protection device with high response capability will be activated at the same time.

● The transmission device is immediately separated, and the slider stops immediately. lf you want to return, you only need to retur the slider to the top dead center position and reset it, and it will automatically recover.

Product Introduction

|

Model |

SKA-110 |

SKA-160 |

SKA-200 |

SKA-260 |

SKA-315 |

|||

|

V |

H |

V |

H |

V |

V |

V |

||

|

Capacity |

Ton |

110 |

160 |

200 |

260 |

315 |

||

|

Rated Tonnage Point |

mm |

6 |

3 |

6 |

3 |

6 |

7 |

7 |

|

Stable Speed |

s.p.m |

30-60 |

60-90 |

20-50 |

40-70 |

20-50 |

20-40 |

20-40 |

|

Speed Changing |

S.p.m |

55 |

35 |

35 |

30 |

30 |

||

|

Stroke |

mm |

180 |

80 |

200 |

90 |

200 |

250 |

250 |

|

Max.Die Hight |

mm |

360 |

410 |

460 |

510 |

460 |

500 |

500 |

|

Slider Adjustment |

mm |

80 |

100 |

110 |

120 |

120 |

||

|

Slide Area |

mm |

910×470×80 |

990×550×90 |

1130×630×90 |

1130×700×100 |

1130×700×100 |

||

|

Bolster Area |

mm |

1150×600×110 |

1250×800×140 |

1400×820×160 |

1500×840×180 |

1600×840×180 |

||

|

Shank Hole |

mm |

φ50 |

φ65 |

φ65 |

φ65 |

φ65 |

||

|

Main Motor |

Kwxp |

11×4 |

15×4 |

18.5×4 |

22×4 |

30×4 |

||

|

Slider Adjust Device |

HP |

Electric |

||||||

|

Air Pressure |

kg/cm² |

6 |

6 |

6 |

6 |

6 |

||

|

Press Precision |

|

GB(JIS)1 class |

||||||

|

Press Dimension (LxWxH) |

mm |

1900×1300×3200 |

2300×1400×3800 |

2615×1690×4075 |

2780×1800×4320 |

2780×1850×4470 |

||

|

Die Cushion Capacity |

mm |

6.3 |

10 |

14 |

14 |

14 |

||

|

Die Cushion Stroke Length |

mm |

80 |

80 |

100 |

100 |

100 |

||

|

Die Cushion Effective Area |

mm² |

500×350 |

650×420 |

710×480 |

810×480 |

810×480 |

||

|

Model |

A |

B |

C |

D |

E |

F |

G |

H |

I |

T |

|

SKA-110 |

400 |

200 |

160 |

650 |

300 |

220 |

φ50 |

220 |

470 |

Il |

|

SKA-160 |

440 |

220 |

220 |

700 |

300 |

175 |

φ65 |

220 |

550 |

II |

|

SKA-200 |

480 |

240 |

280 |

850 |

420 |

200 |

φ65 |

300 |

630 |

II |

|

SKA-260 |

520 |

260 |

290 |

950 |

420 |

200 |

φ65 |

300 |

700 |

Il |

|

SKA-315 |

520 |

260 |

290 |

950 |

420 |

200 |

φ65 |

300 |

700 |

IⅡ |