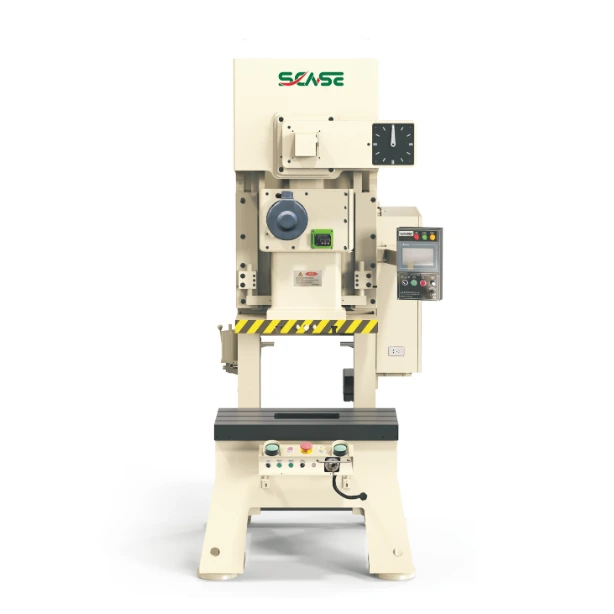

APA Open Type Single Crankshaft High Precision Punch

Features

● To ensure the relative stability of the machine operation, the symmetrical two slide rails and the balancer device design are applied.

● The die precision may be up to 0.1mm and is safe, convenient and reliable.

● The crankshaft, the gear set, the connecting rod, etc. are processed by oxidation and grinding, and have extremely high comprehensiveness and wear resistance performance.

● Highly sensitive and reliable clutch/brake device and internationally leading double solenoid valve and overload protection device are applied to ensure the accuracy and safety of the operation and stop of the press slide.

● The machine structure is designed reasonably, which is convenient for automatic production, reducing costs and improving efficiency.

● Advanced design concept, low noise, low consumption and energy saving.

STANDARD ACCESSORIES

● Touch screen

● Pre-cut counter

● Pre-break counter

● Electronic cam

● Hydraulic overload protection device

● Electric slider adjustment device (≥A1-60)

● Mechanical mold height indicator (≤A1-60)

● Electric mold height indicator (≥A1-60)

● Slider and mold balancing device

● Crankshaft angle indicator

● Air source connector

● Second degree fall protection device

● Misfeed detection device

● Power outlet

● Maintenance tools and toolbox

Optional Accessories

● Electric grease lubrication device

● Air pressure die pad device

● Foot switch

● Quick die change device(Mold lifter,clamp or move arm)

● Slider upper punching device

● Mold lighting device

● Shockproof feet

● Photoelectric protection device

● Feeder(air,machinery and NC types)

● Rack

● Leveler

● Manipulator

|

Model |

APA-25 |

APA-45 |

APA-60 |

APA-80 |

APA-110 |

APA-125 |

APA-160B |

||||||||||

|

|

V |

H |

V |

H |

V |

H |

V |

H |

V |

H |

V |

H |

V |

H |

|||

|

Capacity |

Ton |

25 |

45 |

60 |

80 |

110 |

125 160 |

||||||||||

|

Rated Tonnage Point |

mm |

3.2 |

1.6 |

3.2 |

1.6 |

4 |

2 |

4 |

2 |

6 |

3 |

6 |

3 |

6 |

3 |

||

|

Speed Changing |

s.p.m |

60-140 |

130-200 |

40-100 |

110-150 |

35-90 |

80-120 |

35-80 |

80-120 |

30-60 |

60-90 |

30-60 |

60-90 |

20-50 |

40-70 |

||

|

Stable Speed |

s.p.m |

110 |

75 |

65 |

65 |

55 |

55 35 |

||||||||||

|

Stroke |

mm |

60 |

30 |

80 |

50 |

120 |

60 |

150 |

70 |

180 |

80 |

180 |

80 |

200 |

90 |

||

|

Max.Die Hight |

mm |

200 |

215 |

250 |

265 |

310 |

340 |

340 |

380 |

360 |

410 |

360 |

410 |

460 |

510 |

||

|

Slider Adjustment |

mm |

50 |

60 |

75 |

80 |

80 |

80 |

100 |

|||||||||

|

Slide Area |

mm |

470×230×50 |

560×340×60 |

700×400×70 |

770×420×70 |

910×470×80 |

910×470×80 |

990×550×90 |

|||||||||

|

Bolster Area |

mm |

680×300×70 |

850×440×80 |

900×500×80 |

1000×550×90 |

1150×600×110 |

1150×600×110 |

1250×800×140 |

|||||||||

|

Shank Hole |

mm |

φ38.1 |

φ38.1 |

φ50 |

φ50 |

φ50 |

φ50 |

φ65 |

|||||||||

|

Main Motor |

Kwxp |

3.7×4 |

5.5×4 |

5.5×4 |

7.5×4 |

11×4 |

11×4 |

15×4 |

|||||||||

|

Slider Adjust Device |

|

Manual |

Electric |

||||||||||||||

|

Air Pressure |

kg/cm² |

5-6 |

5-6 |

5-6 |

5-6 |

5-6 |

5-6 |

5-6 |

|||||||||

|

Press Precision |

|

GB(JIS)1 class |

|||||||||||||||

|

Press Dimension(L×W×H) |

mm |

1280×850×2200 |

1600×950×2500 |

1600×1000×2800 |

1800×1180×2800 |

1900×1300×3200 |

1900×1300×3200 |

2315×1400×3490 |

|||||||||

|

Die Cushion Capacity |

mm |

|

2.3 |

3.6 |

3.6 |

6.3 |

6.3 |

10 |

|||||||||

|

Die Cushion Stroke Length |

mm |

|

50 |

70 |

70 |

80 |

80 |

80 |

|||||||||

|

Die Cushion Effective Area |

mm² |

|

300×230 |

350×300 |

450×310 |

500×350 |

500×350 |

650×420 |

|||||||||

|

Model |

APA-160 |

APA-200B |

APA-200 |

APA-260B |

APA-260 |

APA-315 |

APA-400 |

|||||||

|

|

V |

H |

V |

H |

V |

H |

V |

H |

V |

H |

V |

V |

||

|

Capacity |

Ton |

160 |

200 |

200 |

260 |

260 |

315 |

400 |

||||||

|

Rated Tonnage Point |

mm |

6 |

3 |

6 |

3 |

6 |

3 |

6 |

3 |

7 |

3.5 |

7 |

8 |

|

|

Speed Changing |

s.p.m |

20-50 |

40-70 |

20-50 |

40-70 |

20-50 |

50-70 |

20-50 |

50-70 |

20-40 |

40-50 |

20-40 |

20-35 |

|

|

Stable Speed |

s.p.m |

35 |

35 |

35 |

35 |

30 |

30 |

30 |

||||||

|

Stroke |

mm |

200 |

90 |

200 |

90 |

200 |

100 |

200 |

100 |

250 |

150 |

250 |

300 |

|

|

Max.Die Hight |

mm |

460 |

510 |

460 |

515 |

460 |

510 |

460 |

510 |

500 |

550 |

500 |

500 |

|

|

Slider Adjustment |

mm |

100 |

110 |

110 |

110 |

120 |

120 |

120 |

||||||

|

Slide Area |

mm |

990×550×90 |

1050×600×90 |

1130×630×90 |

1130×630×90 |

1130×700×100 |

1130×700×100 |

1200×700×100 |

||||||

|

Bolster Area |

mm |

1250×800×140 |

1400×820×160 |

1400×820×160 |

1500×820×160 |

1500×840×180 |

1600×840×180 |

1800×840×200 |

||||||

|

Shank Hole |

mm |

φ65 |

φ65 |

φ65 |

φ65 |

φ65 φ65 |

φ65 |

|||||||

|

Main Motor |

Kwxp |

15×4 |

18.5×4 |

18.5×4 |

22×4 |

22×4 |

30×4 |

37×4 |

||||||

|

Slider Adjust Device |

|

Electric |

||||||||||||

|

Air Pressure |

kg/cm² |

5-6 |

5-6 |

5-6 |

5-6 |

5-6 |

5-6 |

5-6 |

||||||

|

Press Precision |

|

GB(JIS)1 class |

||||||||||||

|

Press Dimension(L×W×H) |

mm |

2300×1400×3800 |

2315×1500×3670 |

2615×1690×4075 |

2780×1800×4320 |

2615×1790×4075 |

2780×1850×4470 |

3250×2150×4600 |

||||||

|

Die Cushion Capacity |

mm |

10 |

10 |

14 |

14 |

14 |

14 |

14 |

||||||

|

Die Cushion Stroke Length |

mm |

80 |

80 |

100 |

100 |

80 |

100 |

100 |

||||||

|

Die Cushion Effective Area |

mm² |

650×420 |

650×420 |

710×480 |

810×480 |

710×480 |

810×480 |

810×480 |

||||||