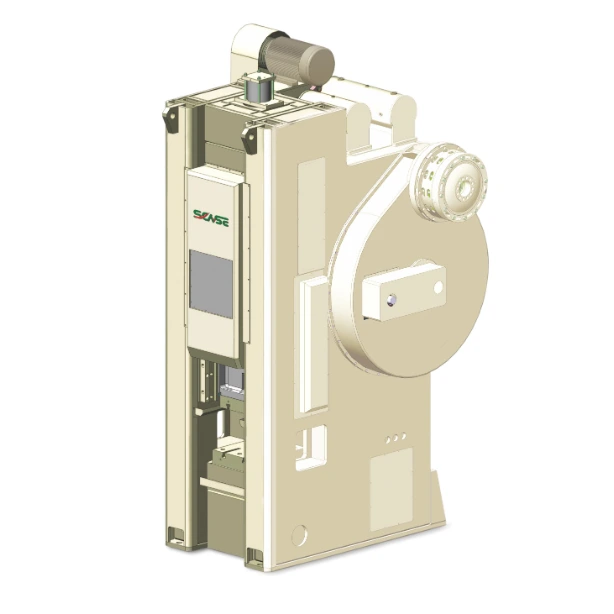

SDP Elbow Joint Single Station Cold Forging Machine

● The SDP series products adopt similar Japanese product technology and are supervised by Taiwanese engineers, which can reach the current level of similar products in Taiwan.

● The body is welded with a combination box type copper plate, and stress is eliminated through annealing heat treatment and surface sandblasting treatment.

● The crankshaft runs horizontally across the body and is forged from high-quality alloy.

● The slider adopts an ultra wide fixed locking eight sided guide rail with high guiding accuracy.

● Adopting a separate clutch brake, with high torque, excellent braking effect, quick response, and sensitive action.

● The automatic oil feeding device provides the best protection for the machine.

● The elbow type punch structure has a unique slider curve where the speed has become very slow near the bottom dead center (compared to crankshaft punches), and the position accuracy of the bottom dead center is high.

● Punching machines are suitable for heavy-duty stamping processes such as embossing, finishing and workpiece extrusion forming.

STANDARD ACCESSORIES

| Model | SDP-250 | SDP-400 | SDP-650 | SDP-800 | SDP-1000 | SDP-1600 | SDP-2000 | SDP-3000 | |

| Capacity | KN | 2500 | 4000 | 6500 | 8000 | 10000 | 16000 | 20000 | 30000 |

| Stroke | mm | 120 | 140 | 180 | 180 | 200 | 220 | 220 | 250 |

| Rated Tonnage Point | mm | 4 | 5 | 8 | 8 | 8 | 8 | 8 | 8 |

| Stable Speed | s.p.m | 50 | 50 | 35 | 35 | 30 | 30 | 25 | 20 |

| Speed Changing | s.p.m | 40~55 | 40~55 | 25~40 | 25~40 | 25~35 | 20~30 | 20~30 | 18~25 |

| Stroke | s.p.m | 20 | 20 | 15 | 15 | 10 | 8 | 8 | 8 |

| Die Height | mm | 370 | 400 | 400 | 400 | 500 | 550 | 550 | 600 |

| Slider Adjustment | mm | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Dimension of Workbench | mm | 500x600 | 550x650 | 600x700 | 600x700 | 700x800 | 900x900 | 1000x1000 | 1100x1100 |

| Area of Slider | mm | 400x420 | 400x500 | 450x550 | 450x550 | 550x650 | 700x800 | 800x900 | 900x1000 |

| Platform Thickness | mm | 100 | 120 | 150 | 150 | 180 | 220 | 250 | 250 |

| Variable-Speed Main Motor | KW | 18.5 | 30 | 45 | 45 | 55 | 75 | 110 | 160 |

| Slider Adjustment Motor | Kwxp | 1.5x6 | 1.5x6 | 2.2x6 | 2.2x6 | 2.2x8 | 5.5x6 | 5.5x6 | 5.5x6 |

| Air Pressure | Kg/cm² | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Precision JIS=(Japan Industrial Grade) |

JIS-1 | JIS-1 | JIS-1 | JIS-1 | JIS-1 | JIS-1 | JIS-1 | JIS-1 | |

| Ejecting Material Capacity | KN | 100 | 150 | 300 | 300 | 500 | 600 | 700 | 900 |

| Ejecting Material Stroke | mm | 50 | 50 | 60 | 60 | 60 | 70 | 70 | 80 |